Reactor

CKSG

In the low-voltage reactive power compensation cabinet, it is connected in series with the capacitor. When there are a large number of harmonic sources such as rectifiers and converters in the low-voltage power grid, the high-order harmonics generated by them will seriously endanger the safe operation of the main transformer and other electrical equipment. After the reactor is connected in series with the capacitor, it can effectively absorb the harmonics of the power grid, improve the voltage waveform of the system, improve the power factor of the system, and effectively suppress the closing inrush current and operating overvoltage, effectively protecting the capacitor.

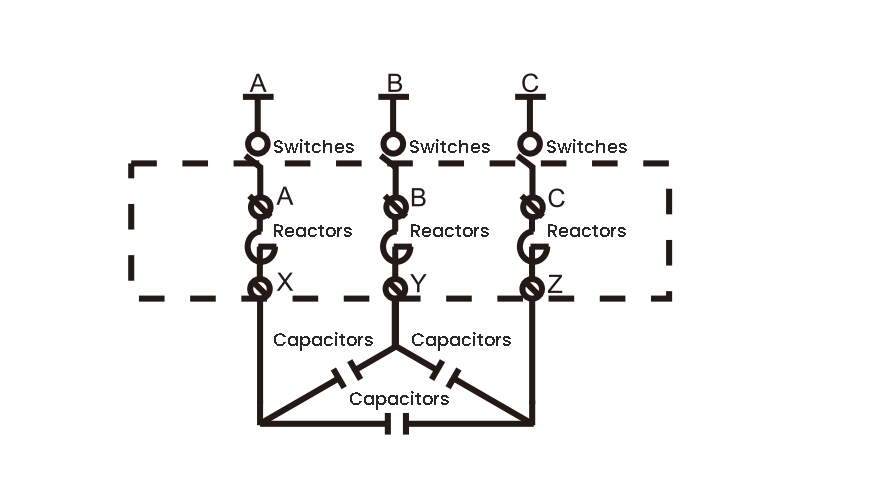

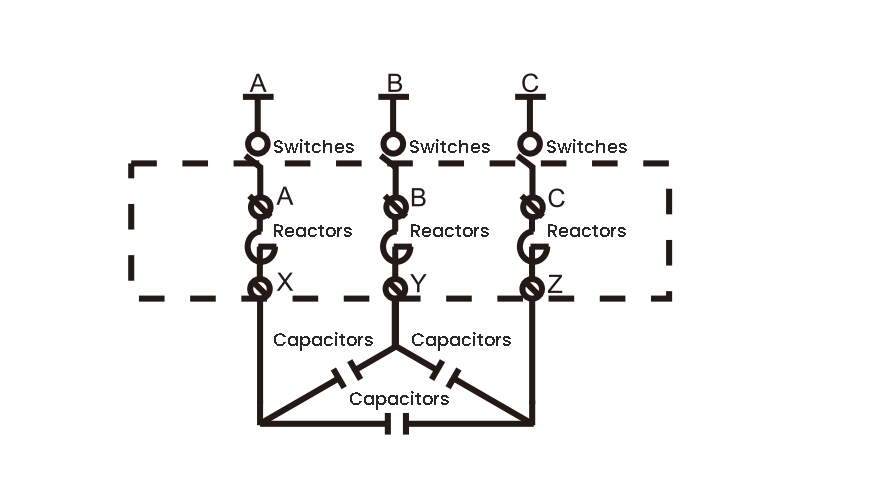

1. ApplicationThis series of dry-type iron core series reactors are used in low-voltage reactive compensation cabinets and are connected in series with capacitors. When there are a large number of harmonic sources such as rectifiers and converters in the low-voltage power grid, the high-order harmonics generated by them will seriously endanger the safe operation of the main transformer and other electrical equipment. After the reactor is connected in series with the capacitor, it can effectively absorb the harmonics of the power grid, improve the voltage waveform of the system, improve the power factor of the system, and effectively suppress the closing inrush current and operating overvoltage, effectively protecting the capacitor.2. Structural features1. The reactor is divided into three-phase and single-phase types, both of which are iron core dry type.2. The iron core is made of high-quality low-loss imported cold-rolled oriented silicon steel sheets, and the core column is divided into uniform small sections by multiple air gaps. The air gaps are separated by epoxy laminated glass cloth boards to ensure that the reactor air gap does not change during operation.3. The coil is wound with H-class or C-class enameled flat copper wire, which is tightly and evenly arranged, and has no insulating layer on the surface. It has excellent aesthetics and good heat dissipation performance.4. After the coil and core of the reactor are assembled into one, they are pre-baked, vacuum-impregnated, and then heat-baked and cured. H-class impregnated paint is used to firmly combine the coil and core of the reactor, which not only greatly reduces the noise during operation, but also has an extremely high heat resistance level, ensuring that the reactor can operate safely and noiselessly at high temperatures.5. The fasteners of the reactor core column are made of non-magnetic materials to ensure that the reactor has a high quality factor and low temperature rise, ensuring a good filtering effect.6. The exposed parts are all treated with anti-corrosion, and the lead terminals are tinned copper tube terminals.7. Compared with similar domestic products, this reactor has the advantages of small size, light weight, and beautiful appearance, which can be comparable to well-known foreign brands.3. Use environment1. The altitude does not exceed 2000 meters.2. The operating environment temperature is -25℃~+45℃, and the relative humidity does not exceed 90%.3. There are no harmful gases and flammable and explosive items around.4. The surrounding environment should have good ventilation conditions. If installed in a cabinet, ventilation should be installed.4. Installation and use1. The reactor should be installed indoors with good ventilation, or it can be installed together with the capacitor bank in a cabinet with good ventilation conditions. The temperature in the cabinet should not exceed 40°C.2. From the perspective of limiting the closing inrush current and suppressing harmonic current, when the reactor is connected in series with the parallel capacitor bank, the reactor can be connected at any position, but generally the reactor is connected in series after the switch and at the front end of the capacitor (see figure):

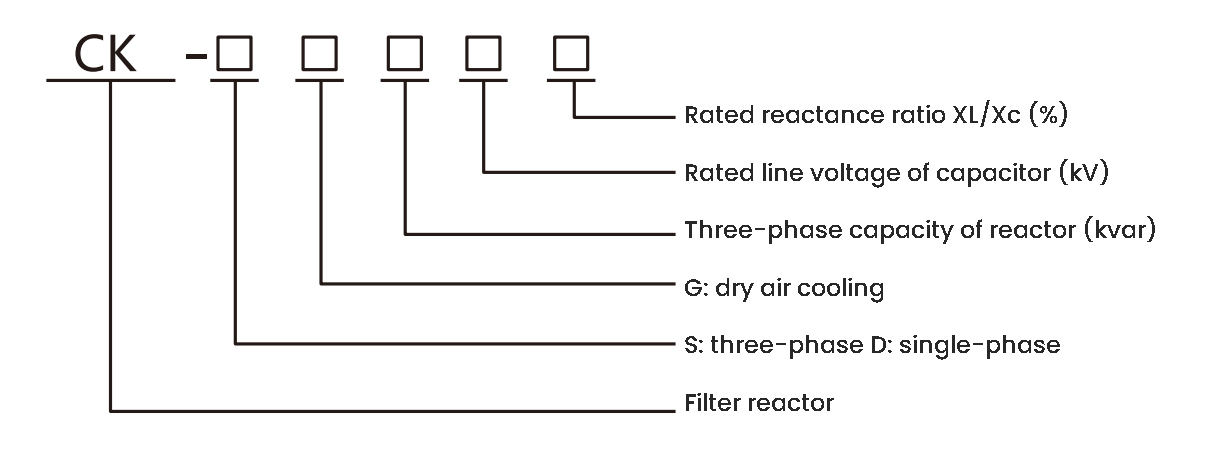

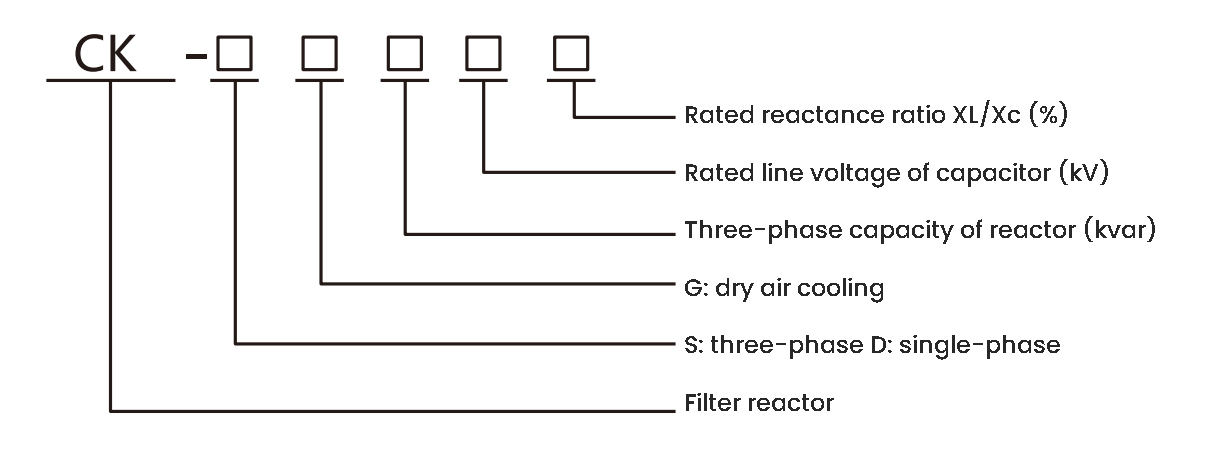

5. Model description

5. Model description

Performance indicators and technical parameters

1. Can be used for 400V and 660V systems.

2. Types of reactance: 7%, 14%.

3. Rated insulation level 3kV/min.

4. Temperature rise limit of each part of the reactor: core temperature does not exceed 85K, coil temperature does not exceed 95K.

5. Reactor noise is not more than 45dB.

6. The reactor can operate for a long time at a power frequency plus harmonic current not more than 1.35 times the rated current.

7. Reactance value linearity: The ratio of the reactance value at 1.8 times the rated current to the reactance value at the rated current is not less than 0.95.

8. The difference between the reactance values of any two phases of the three-phase reactor is not more than ±3%.

9. Temperature resistance grade H (180℃) or above.