Copyright © Zhejiang Yidek Technology Co., Ltd. All Rights Reserved. Site Map

- +86-577-85600688

+86-17758121688 - grace@yidek.com

- No. 397 Binhai 21st Road, Xinghai Street, Longwan District, Wenzhou City

Introduction

According to the 12th Five-Year Plan for the Development of Electric Vehicle Technology , 400,000 charging piles and 2,000 charging and swapping stations will be built by the end of 2015. However, by the end of 2014, only 28,000 charging piles and 723 charging stations had been built nationwide, and the ratio of new energy vehicles to charging piles was about 4:1, far from the standard of 1:1. The 13th Five-Year Plan formulated by the state has further increased the construction scale of charging piles and charging stations. By 2020, the number of charging piles will reach 4.5 million and the number of charging and swapping stations will develop to 12,000.

The rapid development of charging piles

1.1 Development of Charging Pile

With the improvement of technology in various industries, the requirements for power quality are getting higher and higher. On December 28, 2015, the General Administration of Quality Supervision, Inspection and Quarantine, the Standards Committee of the People's Republic of China, the National Energy Administration, the Ministry of Industry and Information Technology, the Ministry of Science and Technology and other departments jointly issued five newly revised national standards for electric vehicle charging interfaces and communication protocols in Beijing. The new standards have been implemented since January 1, 2016, but has the implementation of the new standards really completely solved the problems of the charging pile industry?

In terms of safety, the new standard adds functions such as charging interface temperature monitoring, electronic lock, insulation monitoring and discharge circuit, refines the safety protection measures of the DC charging vehicle-end interface, and explicitly prohibits the use of unsafe charging modes. It can effectively avoid accidents such as electric shock to people and equipment burning, and ensure the safety of electric vehicles and users during charging.

In terms of compatibility, the type and structure of AC and DC charging interfaces are compatible with the original standards. The new standards have modified the sizes of some contacts and mechanical locks, but the old and new plugs and sockets can work with each other. The electronic locking device added to the DC charging interface does not affect the electrical connection between the new and old products. Users only need to update the communication protocol version to ensure the basic charging functions of new power supply equipment and electric vehicles.

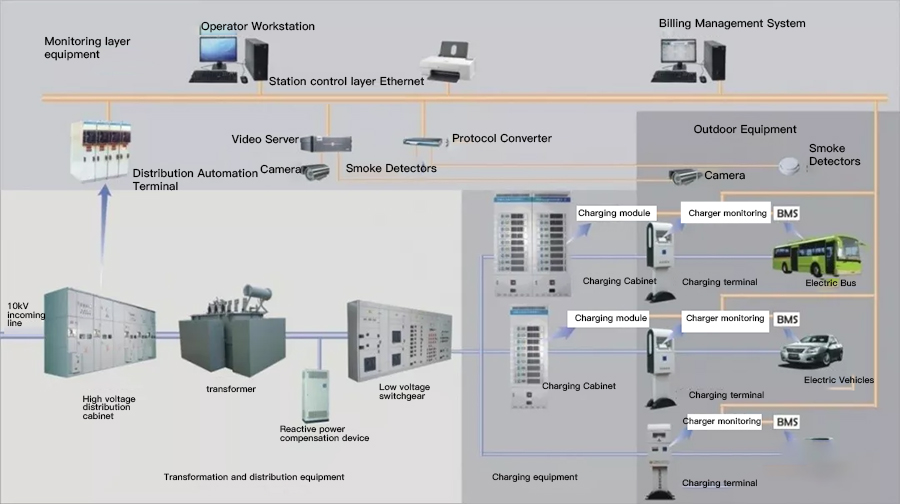

1.2 Schematic diagram of the charging pile system

1.3 Charging pile system

The charging pile system is composed of five major systems: power transformation and distribution equipment system, charging equipment system, outdoor equipment system, and monitoring layer equipment system. The high voltage transmitted from the power grid is stepped down to low voltage through high voltage distribution and transformer, and then transmitted to the charging pile through the low voltage switch. The charging cabinet then rectifies, filters, and amplifies the current to make the voltage and current reach the required values.

The new standard only makes the industry more standardized and unified, but this is mainly aimed at outdoor equipment systems, namely charging pile interfaces, etc., and does not make a requirement for power quality. Therefore, the charging pile industry often misses power quality issues, such as common imbalance, flicker, fluctuation, harmonics, etc., but harmonic pollution is the first among them.

2.1 Charging pile harmonic pollution

In the production process of BRT electric vehicle batteries, three-phase bridge rectifiers composed of thyristors are generally used as formation equipment, but these devices cause high-power power electronic nonlinear loads to the power grid, thereby causing a large amount of harmonic pollution to the power grid. Harmonic problems are more directly harmful to the charging industry:

1. For the outside of the power system, harmonics will cause serious interference to communication equipment and electronic equipment, which is particularly likely to cause errors in cost calculation and lead to costs deviating from reality.

2. Harmonics can cause local parallel resonance or series resonance in the power system, amplifying the harmonic content and causing capacitors and other equipment to burn out.

3. Harmonics can also cause malfunction of relay protection and automatic devices, resulting in confusion in electricity metering.

4. Harmonics reduce the efficiency of electric energy production, transmission and utilization, cause electrical equipment to overheat, age the insulation, shorten its service life, and even cause failure or burnout.

2.2 How to solve the harmonic problem of charging piles

It is mainly dealt with from the following four aspects:

1. Install YDK-SVG static VAR generator to improve the power supply system's ability to withstand harmonics.

2. Install filtering devices (including passive filtering and active filtering devices).

3. Unify charging pile standards and select core control modules with anti-interference capabilities.

4. Manage power quality issues in accordance with national standards.

Wenzhou Bus BRT Longwan Transportation Center Charging Pile Case Sharing

2.3 Charging pile power quality management project

Some Case Studies in 2015

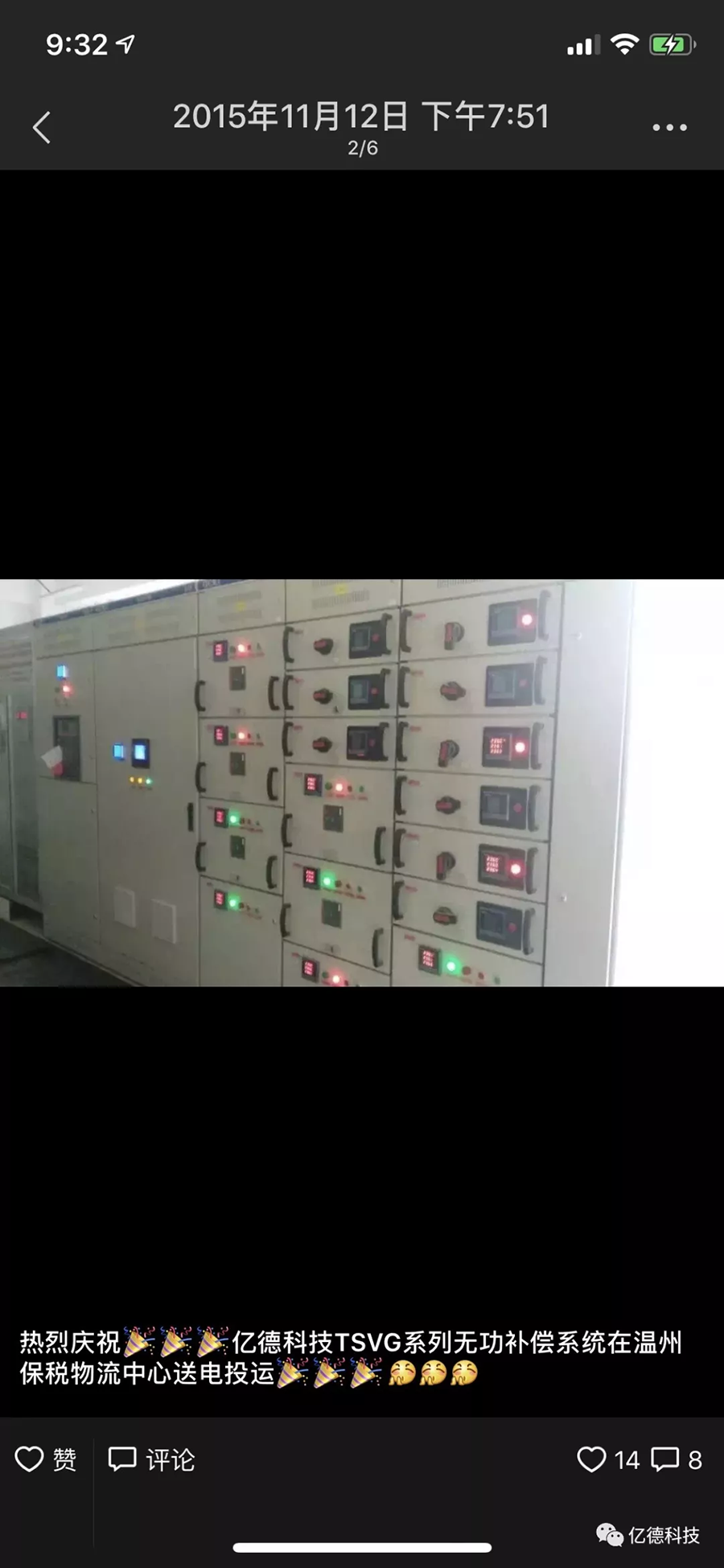

2.4 Bonded Logistics Center TSVG Case

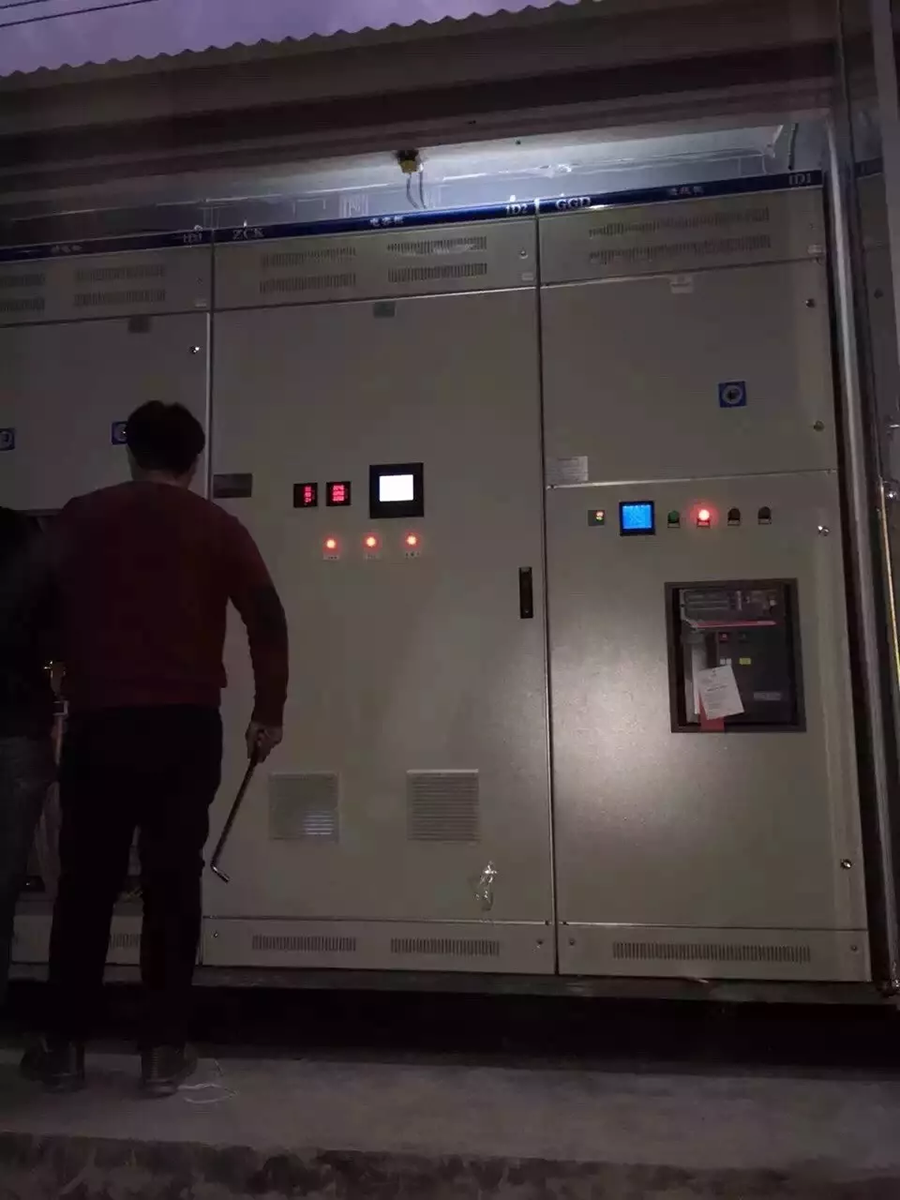

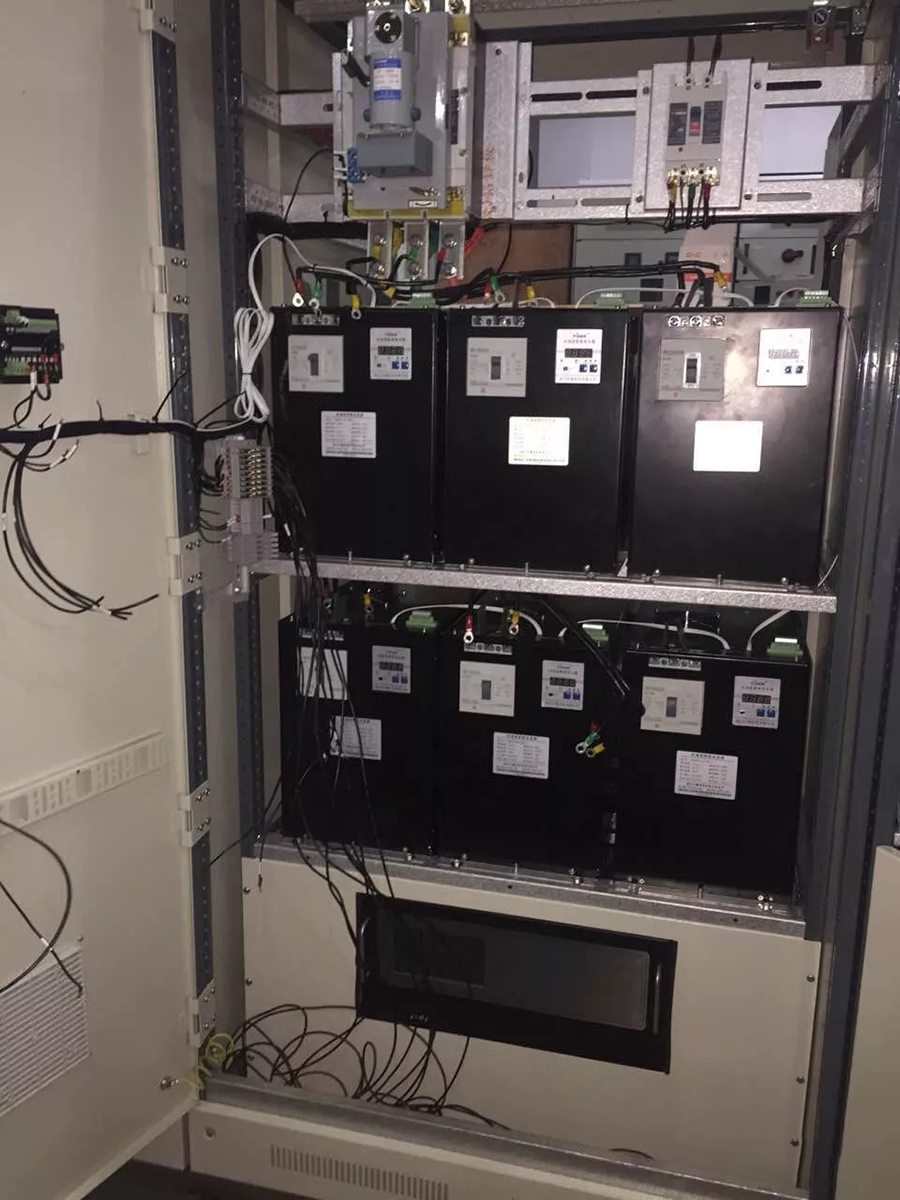

01Charging pile distribution room

02Reactive power compensation cabinet

Some case studies in 2016

2.5 Vienna International Hotel Project

Some Case Studies in 2017

2.6 Wenzhou Agricultural Bank Head Office (Wenzhou Convention and Exhibition Center)

Some case studies in 2018

2.7 Power distribution for the new plant of Aihao Pen Industry

Some case studies in 2019

2.8 Power Distribution of Benuo Laser Industrial Park

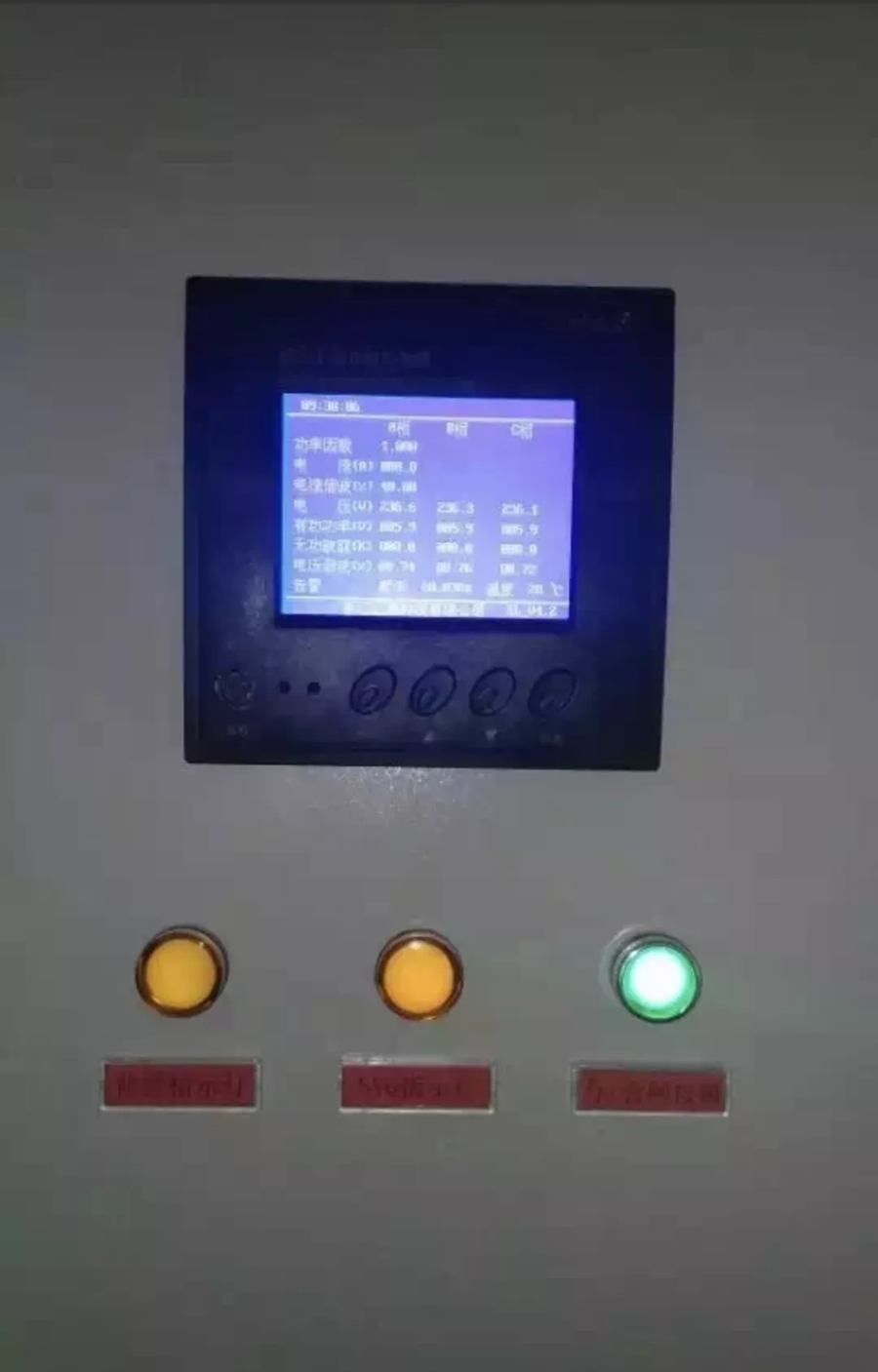

TSVG low voltage dynamic compensation cabinet

■ High efficiency - response time is less than 10ms

■ Authoritative certification——National CCC authoritative certification

■ Monitoring and warning - Automatically record power quality statistics, record events, interference, etc., and issue real-time warnings when exceeding limits

■ Accurate compensation - fifth-generation IGBT, high-speed switching frequency, and extremely low switching loss.

04Technology Improvement

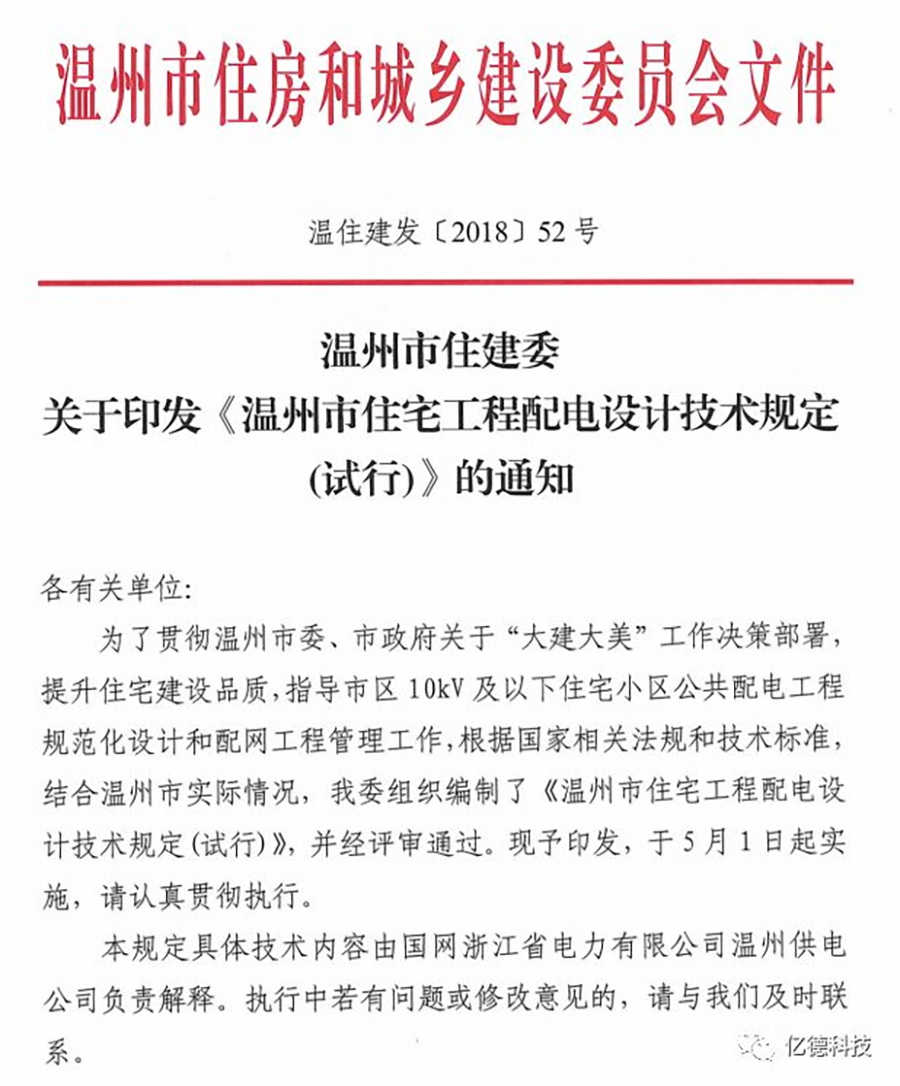

So far, we have been constantly innovating and upgrading our technology to deal with this load phenomenon. In May 2018, Wenzhou Municipal Housing and Urban-Rural Development Committee issued the instruction 4.2.10 in the document "Trial Technical Regulations for Power Distribution Design of Residential Projects in Wenzhou"

Once again, technological innovation adopts a new generation of pre-charged synchronous switches, the fifth generation of IGBT, FPGA+ARM control core and manufacturing process to ensure high stability and enhance the power quality of users.

Conclusion

China has become the world's largest charging pile market, and the operation of large-scale charging infrastructure has brought new challenges to power services. On the other hand, the increase in electric vehicles has also increased the demand for high-current power supply stability, and some unreasonable wiring may also increase the risk of protection tripping of distribution networks at all levels, bringing greater potential safety hazards in electricity use, which also poses a great challenge to the safety management of the distribution system. In the face of these electrical problems in the charging pile industry, Yide Technology has been continuously developing and innovating high-quality products that meet the market demand for charging pile power quality issues, while creating low-voltage component solutions for charging pile power quality issues, and focusing on rapidly promoting the standardization of charging facilities to ensure the reliability of charging pile equipment. Yide Technology will continue to work hard to further enhance its innovation capabilities, strive to provide solutions to charging pile power quality issues, and lead the electrical industry with five-star quality and five-star service!